Understanding Global Manufacturing Standards for Best Solar DC Fuse with Four Key Advantages

The global solar energy market has witnessed exponential growth, with reports estimating that it will surpass $223 billion by 2026, driven by the increasing demand for renewable energy solutions. Central to this expansion is the need for reliable components that ensure system efficiency and safety, particularly in photovoltaic systems. One such essential component is the Solar DC Fuse, designed to protect solar circuits from overcurrent and prevent potential fire hazards. According to the International Renewable Energy Agency (IRENA), implementing high-quality fuses can increase solar system reliability by up to 20%. Understanding global manufacturing standards for Solar DC Fuses not only helps manufacturers deliver superior products but also provides consumers with peace of mind. This ultimate guide delves into the four key advantages of choosing the best Solar DC Fuses, emphasizing their critical role in enhancing solar energy efficiency and safety in a rapidly evolving market.

Importance of Global Manufacturing Standards in Solar Fuse Production

Global manufacturing standards play a crucial role in the production of solar DC fuses, ensuring that these essential components meet high safety and performance benchmarks. These standards are designed to unify the manufacturing process across different regions, providing guidelines that help maintain quality and reliability in the solar industry. As the demand for renewable energy rises, adhering to established international standards becomes increasingly important to facilitate trust among manufacturers, installers, and end-users.

One significant advantage of implementing these global standards in solar fuse production is the enhancement of safety. When fuses are manufactured to comply with recognized criteria, the risk of failure due to poor workmanship or substandard materials is significantly reduced. This is particularly vital in solar applications, where equipment must endure various environmental conditions and operate efficiently over long periods. Additionally, global standards promote interoperability, allowing fuses from different manufacturers to work seamlessly within diverse systems, thus boosting overall system performance and reliability. By prioritizing these standards, the solar industry not only safeguards its investments but also builds a sustainable future through cooperation and innovation.

Key Advantages of High-Quality Solar DC Fuses in the Market

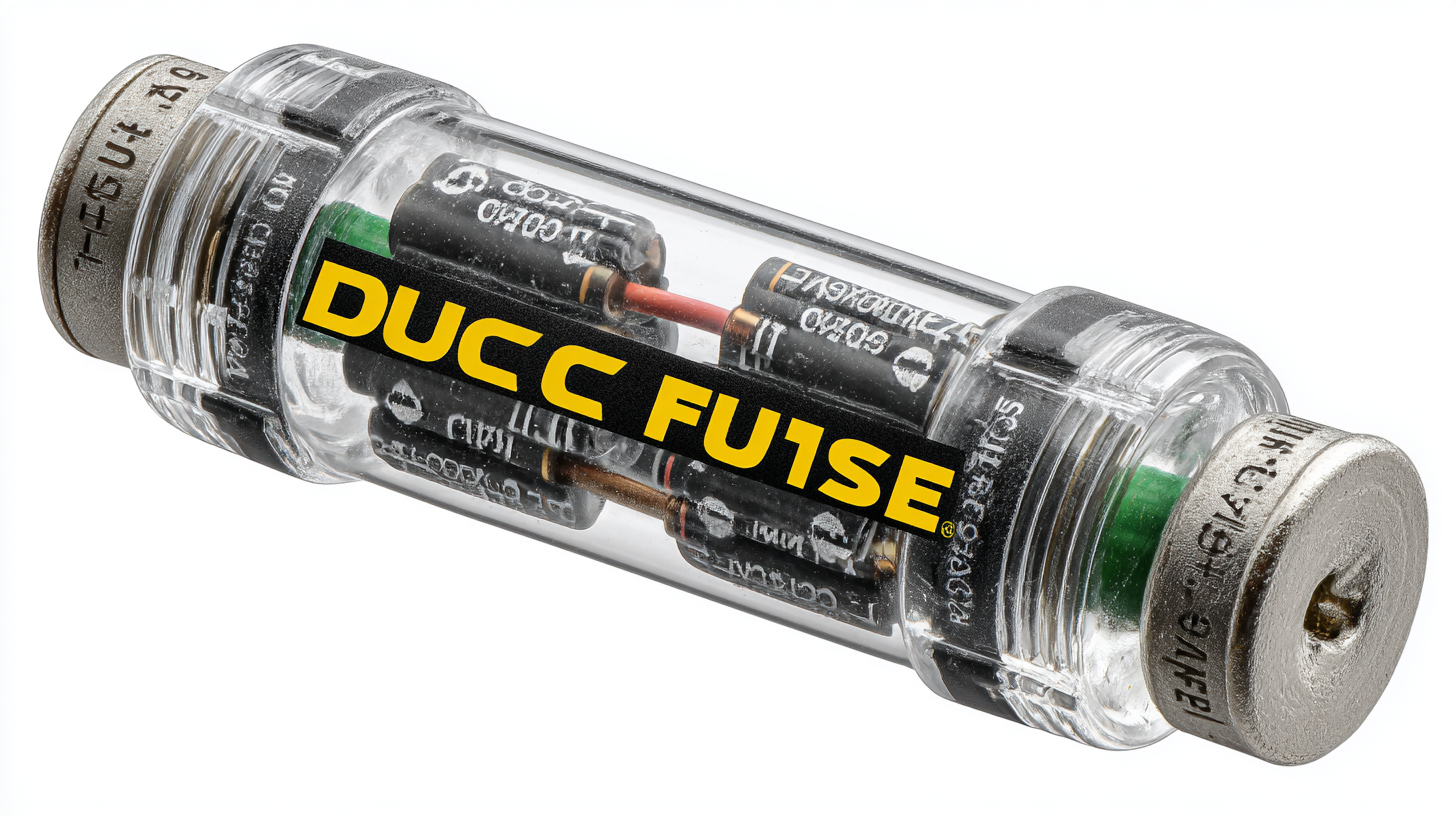

In today's rapidly growing solar industry, the role of high-quality solar DC fuses cannot be overstated. These fuses serve as critical safety components, designed to protect against overcurrent conditions that could lead to catastrophic failures in solar power systems. One of the key advantages of using top-tier solar DC fuses is their enhanced reliability. These fuses are engineered to handle the specific electrical demands of solar applications, ensuring consistent performance even in varying environmental conditions.

Another significant benefit of high-quality solar DC fuses is their ability to improve overall system efficiency. By minimizing unnecessary energy losses during operation, these fuses contribute to maximizing the output of solar installations. Furthermore, they often come with better insulation and temperature ratings, which allow for a safer operational environment, reducing the risks of overheating and potential damage to other components within the system.

Lastly, investing in superior solar DC fuses can lead to long-term cost savings. Although they may require a higher initial investment, their durability and lower failure rates mean reduced maintenance and replacement costs over time. This economic advantage not only enhances the sustainability of solar energy projects but also offers peace of mind to investors and consumers alike, knowing that their systems are protected by robust and efficient components.

Understanding Global Manufacturing Standards for Best Solar DC Fuse

Navigating Import and Export Certifications for Solar Products

Navigating the complex landscape of import and export certifications for solar products is crucial for manufacturers and traders alike. In recent years, the global solar market has witnessed significant growth, with installations surpassing 260 gigawatts in 2020 alone, according to the International Renewable Energy Agency (IRENA). This boom in the solar sector demands not only high-quality products but also adherence to international manufacturing standards to ensure safety and efficiency. Understanding certifications such as IEC and UL can empower manufacturers to access new markets and enhance their product’s credibility.

For instance, the IEC 60269 standard governs fuse specifications, which is vital for solar DC fuses. Compliance with these standards can streamline the certification process, allowing quicker entry into various international markets. Moreover, a study by Bloomberg New Energy Finance highlighted that avoiding regulatory hurdles through proper certification could minimize costs by up to 15% during the import and export process. By investing in globally recognized certifications, businesses position themselves favorably amidst increasing competition, ensuring they meet essential quality and safety benchmarks while maximizing their market potential.

How to Choose the Best Solar DC Fuse for Your Applications

When selecting the best solar DC fuse for your applications, it's crucial to consider several key factors. First, understanding the specific electrical characteristics of your solar system is essential. This includes knowing the maximum current rating and voltage level, which will help you choose a fuse that can handle the electrical load safely and effectively.

Tips for selecting the right fuse include checking for compliance with global manufacturing standards, as this ensures the fuse has been tested for reliability and safety. Additionally, consider the fuse's response time to overcurrent situations; a fast-acting fuse can prevent damage to your system by interrupting the flow of electricity quickly when a fault occurs.

Another critical aspect is the fuse's physical size and mounting options, which should fit within your existing system design. Ensure that the fuse you choose is compatible with your layout to facilitate easy installation and maintenance. By keeping these factors in mind, you can effectively select the best solar DC fuse that meets the demands of your application, ensuring optimal performance and longevity.

Understanding Regulatory Compliance in Global Solar Manufacturing

In the rapidly evolving solar manufacturing landscape, regulatory compliance has become paramount for ensuring product quality and safety. The International Electrotechnical Commission (IEC) sets critical standards that dictate design and performance requirements for solar components, including DC fuses. Adhering to these guidelines is not just a matter of meeting industry expectations; it significantly reduces the risk of failures and enhances the longevity of solar installations. According to a report by the Global Solar Council, compliance with international standards can lead to a 30% decrease in product failure rates, highlighting the necessity for manufacturers to prioritize these regulations.

Moreover, as various regions develop their own compliance regulations, such as the National Electrical Code (NEC) in the United States, manufacturers must navigate these complex requirements to remain competitive. Research indicates that companies prioritizing compliance not only achieve higher sales growth—up to 25% in some cases—but also benefit from enhanced brand reputation and customer trust. With investments in reliable solar solutions continuing to soar, understanding and adhering to global manufacturing standards is essential for manufacturers aiming to capture a wider market while providing safe and efficient solar energy solutions.